Sealcoating is an essential maintenance technique that protects and prolongs the lifespan of asphalt surfaces such as driveways, parking lots, and roads. Understanding how to optimize the cost of sealcoating without compromising quality is crucial for property managers, homeowners, and municipal agencies alike. This guide provides comprehensive insights into reducing the cost of sealcoating while maintaining its effectiveness.

Importance of Cost-Efficiency in Maintaining Large Paved Areas Like Driveways, Parking Lots, and Roads

The cost-efficiency of maintaining large paved areas cannot be overstated. Regular maintenance not only extends the lifespan of these surfaces but also prevents the high costs associated with full-scale repairs or replacements. Efficiently managing the cost of sealcoating can result in significant savings, especially over the long term. Here are some key points that highlight the importance:

- Prevents Deterioration: Regular sealcoating prevents the rapid deterioration of asphalt due to weather, oil, and chemical exposure.

- Reduces Repair Costs: By maintaining the integrity of the pavement, sealcoating reduces the need for costly repairs such as filling cracks and patching potholes.

- Enhances Appearance: A well-maintained driveway or parking lot improves curb appeal, potentially increasing property values.

- Safety Improvements: Smooth and well-maintained surfaces reduce the risk of accidents for vehicles and pedestrians.

- Longevity: Sealcoating can double the life of a driveway or parking lot by providing a protective layer that resists wear and tear.

- Cost-Effective: Compared to the high cost of asphalt replacement, sealcoating is an affordable preventative measure.

- Environmental Protection: Sealcoating helps protect the asphalt from spills and leaks of oil and chemicals, which can be costly to clean up and detrimental to the environment.

Understanding the Costs of Sealcoating

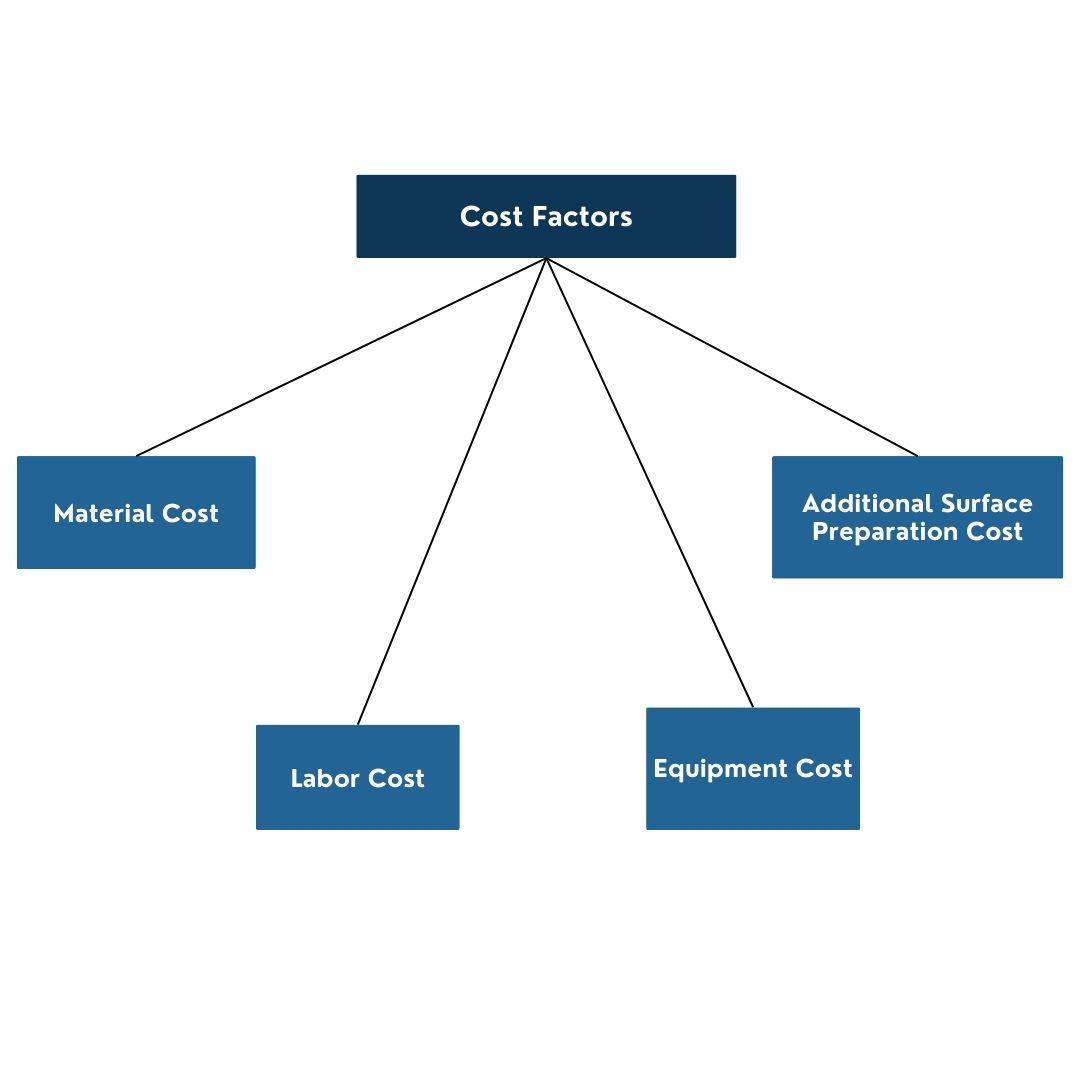

Understanding the costs involved in sealcoating is crucial for budgeting and ensuring cost-effective maintenance of paved surfaces. The overall expenses can vary widely depending on several factors including the cost of sealcoating, asphalt sealing cost, and the average cost to seal a driveway. Additionally, prices may differ based on the specific requirements. Let’s get it more in detail:

Breakdown of Costs

The total cost to sealcoat an asphalt driveway typically includes materials, labor, equipment, and sometimes, additional surface preparation costs. Material costs can vary depending on the grade of the sealant and the size of the area to be covered.

Influencing Factors

Several factors influence the asphalt sealing cost. These include the condition of the surface, the geographic location, the size of the area, and the type of sealant used. For instance, a heavily cracked or damaged driveway may require extensive prep work, thereby increasing the overall costs.

Preparation: Key to Reducing Costs

Proper preparation is critical to reducing the overall cost to seal a driveway professionally. Cleaning and patching potholes or large cracks before the sealcoating application can prevent the need for reapplication too soon after the initial job, thus saving money in the long run. Effective preparation involves several key steps:

- Thorough Cleaning: Remove all dirt, debris, and vegetation from the surface. This ensures that the sealcoat adheres properly to the asphalt.

- Repairing Cracks: Fill in any cracks with a suitable crack filler to prevent water infiltration that can lead to further damage.

- Addressing Oil Stains: Clean oil stains as they can prevent the sealcoat from adhering correctly.

- Leveling Potholes: Patch and level any potholes to ensure a uniform surface, which enhances the effectiveness and aesthetics of the sealcoat.

- Edge Trimming: Trim the grass and other vegetation around the edges of the driveway or parking lot to prevent overgrowth from damaging the asphalt edges.

- Drainage Check: Ensure proper drainage to avoid water pooling on the surface, which can degrade the sealcoat prematurely.

- Dry Surface: The asphalt must be completely dry before applying the sealcoat for optimal adhesion and uniform coverage.

Choosing the Right Materials

Selecting the appropriate sealcoating material can drastically affect both the performance and the cost. High-quality sealants might cost more upfront but can provide better protection and longer-lasting results, which translates to lower costs over time. Key considerations when choosing sealcoating materials include:

- Type of Sealant: Asphalt-based sealants are cost-effective and provide good protection against water, whereas coal tar sealants offer superior resistance to oil, gas, and chemical spills.

- Performance Grade: Opt for high-grade sealants that offer UV protection, flexibility, and longevity, even though they may be more expensive initially.

- Eco-Friendliness: Consider environmentally friendly options that contain fewer Volatile Organic Compounds (VOCs), which are better for the environment and often required by regulations.

- Supplier Reputation: Purchase from reputable suppliers known for quality products. Their experience and reliability can significantly impact the effectiveness of the sealcoat.

- Warranty and Support: Check if the materials come with a warranty or technical support, which can provide additional security and assistance in case of issues.

- Climate Compatibility: Ensure the material is suitable for your local climate. Some sealants perform better in colder temperatures, while others are designed for warmer climates.

- Specific Needs: Evaluate if the sealant meets specific needs such as faster curing times, enhanced color, or improved traction.

Timing Your Sealcoating

The timing of your sealcoating application impacts the effectiveness and longevity of the coat. Applying a sealcoat during moderate temperatures and dry weather conditions can ensure better adhesion and durability, reducing the frequency of reapplication. Applying a sealcoat at correct time can determine how often you should sealcoat your driveway or parking lot. Here are key points to consider for optimal timing:

- Temperature Range: Ideal temperatures for sealcoating are typically between 50°F and 85°F. This range helps ensure the sealant cures properly.

- Dry Conditions: Apply sealcoat when dry weather is expected for at least 24 hours post-application to prevent washing away or diluting the sealant.

- Avoid Hot Temperatures: Extremely hot temperatures can cause the sealcoat to dry too quickly, potentially leading to uneven coverage and less effective protection.

- Seasonal Considerations: Spring and early fall are often the best times to apply sealcoat, as these seasons usually provide the mild temperatures and dry conditions needed for optimal curing.

- Time of Day: Applying a sealcoat in the early morning or late afternoon can avoid the peak daytime temperatures, ensuring a more consistent application.

Bulk Purchasing and Economies of Scale

For large projects, such as sealcoating parking lot costs, buying materials in bulk can lead to significant cost savings. Economies of scale can be a powerful way to reduce the seal coating price per square foot. Here are some advantages and strategies for utilizing bulk purchasing:

- Lower Unit Costs: Purchasing sealcoating materials in larger quantities typically reduces the cost per unit, making it more economical for extensive projects.

- Negotiation Leverage: Larger orders provide more bargaining power with suppliers, potentially leading to further discounts or favorable terms.

- Reduced Shipping Costs: Consolidating purchases can also lower shipping costs per unit, as suppliers often offer discounted or even free shipping for bulk orders.

- Consistency in Material Quality: Bulk purchasing ensures that all materials come from the same batch, leading to a more consistent quality and appearance of the sealcoated surface.

- Waste Reduction: Buying in bulk can reduce packaging waste, which is not only good for cost-saving but also better for the environment.

- Time Efficiency: With sufficient material on hand from a bulk purchase, projects can proceed without delays waiting for additional supplies, thus saving time and potentially reducing labor costs.

Hiring Professionals vs. DIY

Deciding whether to hire professionals or undertake the project as a DIY can significantly impact the cost. While DIY might seem cheaper, the professional application ensures quality and durability. Mistakes in DIY projects can lead to increased costs due to the need for repairs or professional intervention later. Here are several considerations to help determine the best approach:

- Quality and Expertise: Professionals have the expertise and equipment necessary to ensure that the job is done right the first time. They are also knowledgeable about the latest techniques and materials.

- Time and Effort: DIY projects require a significant amount of time and physical effort. If you are not experienced, the project could take longer than expected and potentially yield suboptimal results.

- Cost of Materials and Tools: While hiring professionals includes labor costs, DIY requires purchasing or renting the necessary tools and materials, which can add up quickly.

- Longevity and Performance: Professional applications are generally more durable and last longer due to better preparation and application techniques. This can decrease the frequency of resealing needed, ultimately saving money in the long run.

- Warranty and Liability: Professional seal-coating services often come with a warranty for the work performed. DIY projects carry the risk of errors without recourse for professional correction at no additional cost.

- Safety: Sealcoating involves chemicals that require proper handling. Professionals are equipped to handle these materials safely, reducing the risk of harm.

Regular Maintenance to Extend Lifespan

Regular maintenance, including timely sealcoating, can extend the lifespan of asphalt surfaces. This proactive approach reduces the overall driveway sealing cost by minimizing the need for extensive repairs. Here are key points highlighting the benefits of regular maintenance:

- Prevention of Major Damage: Regular sealcoating shields asphalt from UV rays, water penetration, oils, and chemicals, which can cause significant damage over time if left unprotected.

- Cost Savings: By maintaining the integrity of the pavement through regular upkeep, costly full-scale repairs or complete replacements can be avoided, leading to substantial cost savings.

- Aesthetic Appeal: Regularly maintained roads, driveways, and parking lots look better and offer a positive first impression, which is particularly important for businesses.

- Increased Property Value: Well-maintained asphalt can boost property value, making it a wise investment for residential and commercial property owners.

- Improved Safety: Smooth and well-maintained surfaces are safer for vehicles and pedestrians, reducing the risk of accidents caused by potholes and cracks.

- Efficiency in Maintenance Efforts: Regular maintenance routines allow for easier, quicker, and cheaper repairs since issues are addressed before they become more severe.

Leveraging Technology

Modern technologies and advanced application techniques can enhance the efficiency of sealcoating. Drones, for example, can be used for accurate measurement and assessment, ensuring that the right amount of material is used and waste is minimized. Here’s how technology is making a difference:

- Drones for Assessment: Drones can be employed to survey and measure large areas accurately, providing precise data for how much material is needed, thus preventing over or under-ordering.

- Infrared Technology: This technology can detect weak spots or damages in pavement that are not visible to the naked eye. Addressing these issues early can prevent major repairs later.

- Automated Spreaders: Machines that distribute sealcoat uniformly ensure consistent coverage, reducing material waste and improving surface protection.

- GPS Tracking: GPS-equipped machinery can streamline the sealcoating process by mapping out precise application paths and ensuring that no areas are missed or overlapped.

- Software for Project Management: Specialized software can help in planning and tracking the progress of a sealcoating project, from material procurement to application, ensuring efficiency and adherence to schedules.

- Environmental Sensors: These can monitor conditions such as humidity and temperature in real-time, helping operators choose the optimal time for application to ensure the best possible adherence and curing of the sealant.

Conclusion

Effectively managing the average cost to seal a driveway requires a combination of good preparation, choosing the right materials, and understanding the factors that influence costs. By adopting a strategic approach to sealcoating, property owners can ensure their asphalt investments are protected and costs are kept to a minimum, ensuring both aesthetic appeal and functional longevity.

FAQs On the Cost of Sealcoating

What Is the Asphalt Sealing Cost?

The cost of asphalt sealing typically ranges from $0.15 to $0.25 per square foot, depending on local rates and the condition of the asphalt.

Is Sealcoating Worth the Money?

Yes, sealcoating is worth the investment as it protects asphalt from deterioration, extends its lifespan, and enhances its appearance.

How Do You Estimate Seal Coating Cost?

Estimate seal coating costs by calculating the area in square feet and multiplying it by the cost per square foot, which can vary based on material type and regional prices.

How Much Does It Cost to Seal a Driveway Professionally?

Professionally sealing a driveway typically costs between $0.14 and $0.25 per square foot, influenced by the driveway’s size and condition.

What Is the Cost to Sealcoat a Parking Lot?

The cost to sealcoat a parking lot is generally around $0.20 to $0.30 per square foot, varying with the lot’s size, condition, and type of sealant used.