In parking lots and garages, ensuring safety and organization is paramount. One of the key elements that contribute to this is the use of wheel stops. But what are wheel stops? These crucial devices, also known as concrete bumper stops, concrete parking stops, and rubber parking stops, serve to define parking spaces and prevent vehicles from rolling beyond their designated areas. Wheel stops are integral to effective parking management, working alongside other safety measures like thermoplastic striping, thermoplastic line striping, and thermoplastic markings. This article explores the different types of wheel stops, their role in enhancing parking safety, installation best practices, maintenance tips, legal considerations, and the latest innovations in their design.

Understanding Wheel Stops

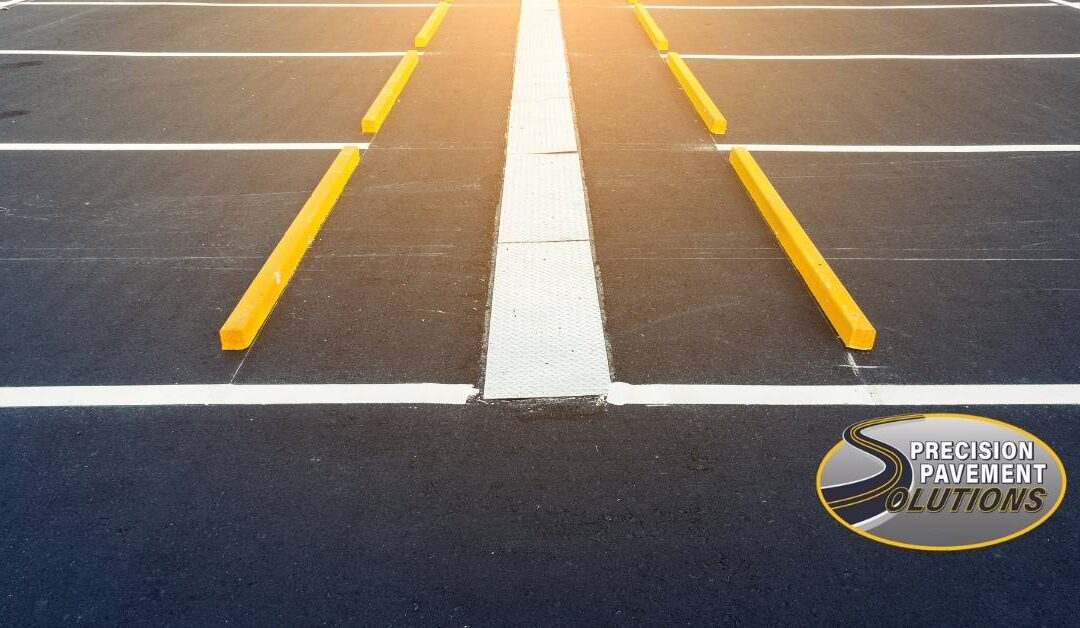

Wheel stops, also known as parking blocks or curb stops, are essential devices used in parking areas to prevent vehicles from rolling beyond designated boundaries. They are typically positioned at the end of parking spaces to ensure that vehicles park within their allotted areas, thereby enhancing safety and organization.

Types of Wheel Stops

Wheel stops come in various materials, each offering unique benefits. Here’s a closer look at the different types:

Concrete Wheel Stops

Concrete bumper stops are the most commonly used type due to their durability and cost-effectiveness. These stops are heavy and resistant to wear and tear, making them ideal for long-term use in various parking settings.

Rubber Wheel Stops

Rubber parking stops are made from durable rubber, often recycled. They are lighter than concrete stops, making them easier to install. Rubber stops are also more flexible, reducing the risk of damage to vehicles upon impact.

Plastic Wheel Stops

Plastic wheel stops are lightweight and easy to handle. They are usually made from recycled plastic, making them an environmentally friendly option. These stops are resistant to weather and chemical damage, ensuring longevity.

Metal Wheel Stops

Metal wheel stops, typically made from steel or aluminum, offer robust performance. They are highly durable and can withstand significant impacts. However, they may require more maintenance to prevent rust and corrosion.

Recycled Material Wheel Stops

Wheel stops made from recycled materials are gaining popularity due to their sustainability. These stops can be made from recycled rubber, plastic, or a combination of materials, offering a green alternative without compromising on performance.

The Role of Wheel Stops in Enhancing Parking Safety

Wheel stops play a pivotal role in enhancing parking safety by preventing vehicles from encroaching on pedestrian pathways and adjacent parking spaces. By providing a physical barrier, wheel stops ensure that vehicles park correctly, reducing the risk of accidents and damage. Whether using concrete parking stops or rubber parking stops, the strategic placement of these devices helps maintain an organized traffic flow within parking areas. Additionally:

Preventing Vehicle Overhang

One of the primary functions of wheel stops is to prevent vehicle overhang. By providing a physical barrier, wheel stops ensure that vehicles do not extend into pedestrian walkways, adjacent parking spaces, or other restricted areas, thus enhancing safety for both drivers and pedestrians.

Organizing Traffic Flow

Wheel stops help in organizing traffic flow within parking lots by clearly demarcating parking spaces. This organization reduces the risk of accidents and ensures that vehicles are parked uniformly, maximizing the available parking space.

Installation Best Practices

Installation of wheel stops from professionals is crucial to their effectiveness and longevity. When installing concrete bumper stops or rubber parking stops, it’s essential to follow correct placement guidelines and installation procedures. Ensuring that wheel stops are securely anchored and positioned correctly can prevent vehicle overhang and enhance overall parking safety. Incorporating thermoplastic striping during installation can also improve the visibility and functionality of the parking area. Moreover:

Correct Placement

For optimal effectiveness, wheel stops should be placed correctly. They should be positioned at a suitable distance from the end of the parking space to accommodate vehicles of various sizes. The placement should also consider accessibility for pedestrians and compliance with local regulations.

Installation Procedures

Proper installation is crucial for the durability and functionality of wheel stops. The installation process may vary depending on the material of the wheel stop but generally involves anchoring the stop securely to the ground. Following manufacturer guidelines and using appropriate tools is essential for a successful installation.

Maintenance and Care for Wheel Stops

Maintaining wheel stops is essential to ensure their continued effectiveness in enhancing parking safety. Regular inspections and timely maintenance can prevent wear and damage. For example, checking concrete parking stops for cracks and rubber parking stops for wear can help identify issues early. Maintenance tips include cleaning debris around the stops, repainting worn areas with thermoplastic markings, and replacing damaged stops promptly to ensure they continue to serve their purpose effectively. Additionally:

Regular Inspections

Regular inspections are necessary to ensure that wheel stops remain in good condition. Inspections should check for cracks, breaks, or signs of wear that might compromise the effectiveness of the stops.

Maintenance Tips

To extend the lifespan of wheel stops, maintenance tips include cleaning debris from around the stops, repainting or marking worn areas, and replacing damaged stops promptly. For thermoplastic markings, regular upkeep ensures visibility and effectiveness.

Legal and Compliance Considerations

When installing wheel stops, it’s crucial to adhere to local regulations and compliance standards to ensure safety and accessibility. Compliance with local regulations may dictate the type, size, and placement of wheel stops. Additionally, ADA (Americans with Disabilities Act) considerations must be taken into account to ensure that wheel stops do not obstruct accessible paths and are installed to accommodate individuals with disabilities. Moreover:

Compliance with Local Regulations

Compliance with local regulations is essential when installing wheel stops. Regulations may dictate the type, size, and placement of wheel stops to ensure safety and accessibility.

ADA Considerations

When installing wheel stops, ADA (Americans with Disabilities Act) considerations must be taken into account. This includes ensuring that wheel stops do not obstruct accessible paths and that they are installed in a way that accommodates individuals with disabilities and meet the expedition for ADA parking dimensions.

Innovations in Wheel Stop Design

Innovations in wheel stop design continue to improve their functionality and durability. New materials, such as advanced composites and environmentally friendly options, offer enhanced performance while reducing environmental impact. Technological advancements, such as reflective coatings and integrated lighting, increase visibility and safety. Here are some notable innovations:

- Advanced Composites: Utilizing materials like Fiberglass-Reinforced Plastic (FRP) and other composites to create wheel stops that are lightweight yet incredibly strong, offering a longer lifespan compared to traditional materials.

- Environmentally Friendly Options: Incorporating recycled materials, such as rubber from old tires or plastic waste, to produce wheel stops that reduce environmental impact while maintaining high performance.

- Reflective Coatings: Adding reflective strips or coatings to wheel stops to enhance their visibility at night and in low-light conditions, reducing the risk of accidents and improving overall parking safety.

- Integrated Lighting: Embedding LED lights within wheel stops to provide continuous illumination, which not only increases visibility but also adds a modern, high-tech appearance to parking facilities.

- Modular Designs: Developing wheel stops with modular components that can be easily assembled, disassembled, or replaced, offering flexibility and cost savings in maintenance and repairs.

- Smart Wheel Stops: Integrating sensors and IoT (Internet of Things) technology to monitor and report on the condition of wheel stops, alerting maintenance teams when replacements or repairs are needed.

- Improved Ergonomics: Designing wheel stops with tapered edges and rounded corners to reduce the risk of tripping for pedestrians and minimize vehicle damage upon contact.

- Customizable Aesthetics: Offering a variety of colors, finishes, and branding options to match the aesthetics of different parking facilities, enhancing the overall appearance and cohesion of the space.

- Anti-Skid Surfaces: Adding textured surfaces or anti-skid coatings to wheel stops to improve traction and prevent vehicles from sliding, especially in wet or icy conditions.

Summary

Wheel stops play a crucial role in enhancing parking safety by preventing vehicle overhang, organizing traffic flow, and ensuring compliance with regulations. Understanding the different types of wheel stops, their installation best practices, and maintenance needs can help property owners make informed decisions. With ongoing innovations, wheel stops are becoming more effective and environmentally friendly, contributing to safer and more organized parking environments.

FAQs on What Are Wheel Stops

What Are Concrete Bumper Stops Used For?

Concrete bumper stops are used to prevent vehicles from rolling beyond their designated parking spaces, enhancing safety and organization in parking lots and garages.

What Are the Benefits of Using Concrete Parking Stops?

Concrete parking stops are durable, cost-effective, and resistant to weather and impact, providing long-term reliability and effective vehicle containment.

How Effective Are Rubber Parking Stops Compared to Other Materials?

Rubber parking stops are highly effective due to their flexibility, ease of installation, and ability to reduce vehicle damage upon impact, making them a popular choice for many parking areas.

What Is Thermoplastic Striping and Where Is It Commonly Used?

Thermoplastic striping is a durable pavement marking material commonly used on roads and parking lots for its high visibility and long-lasting performance.

How Is Thermoplastic Line Striping Applied to Parking Lots and Roadways?

Thermoplastic line striping is applied using specialized equipment that heats and sprays the material onto the surface, where it cools and hardens to form durable, high-visibility markings.

What Are Thermoplastic Markings and What Advantages Do They Offer?

Thermoplastic markings are durable, reflective pavement markings that offer long-lasting visibility and resistance to wear and weather, making them ideal for high-traffic areas.